Quebec | CA

East Coast Catalytic Converter Processing

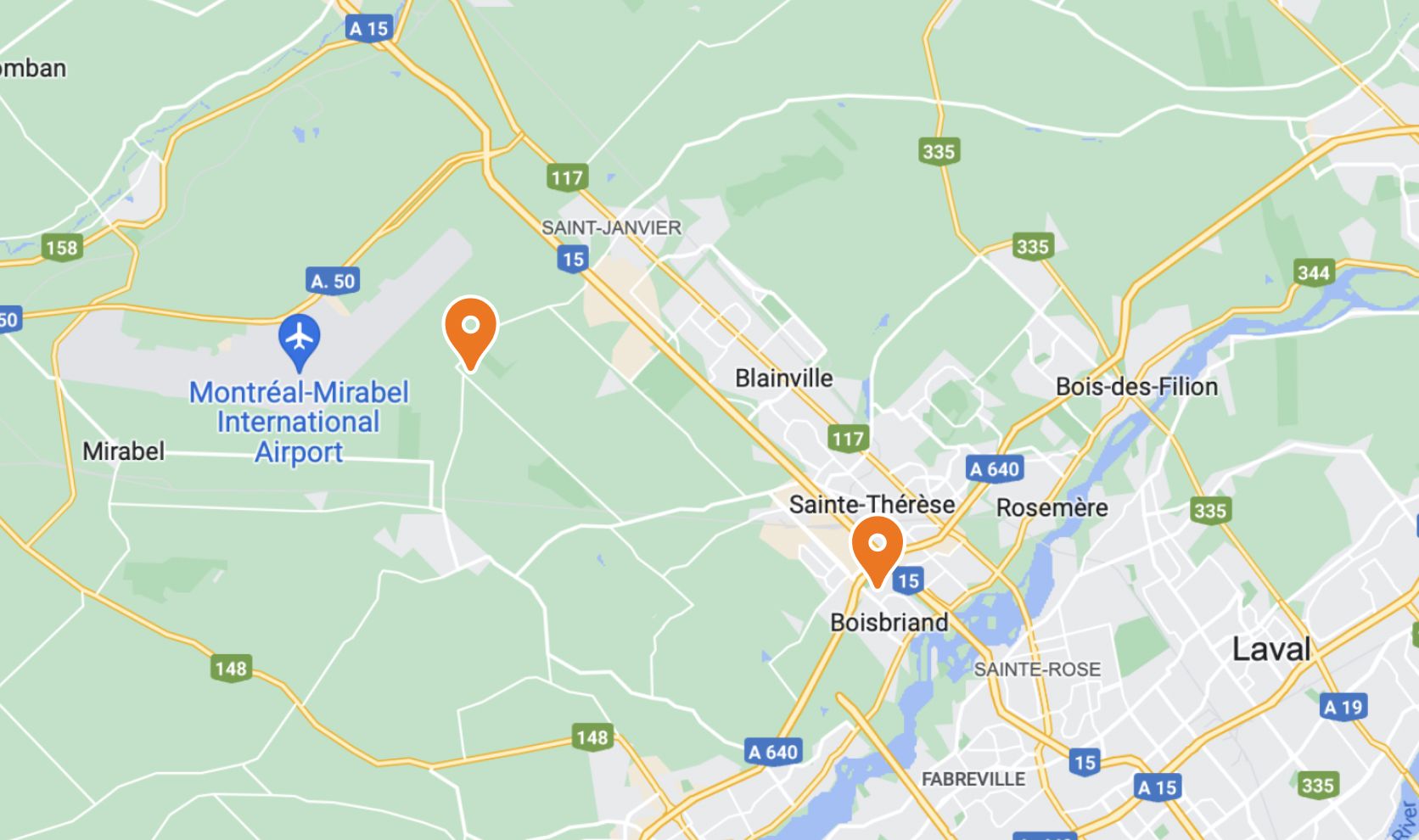

Access economical shipping solutions for your catalyst material when you ship to PMR’s Boisbriand and Mirabel facilities. Get refining solutions for all your foil processing needs through Mirabel’s cutting-edge machinery that has increased foil processing proficiency. Receive tailored processing solutions for your ceramic material with our Boisbriand facility’s innovative technology specialized in ceramic processing.

We give tailored and personalized assistance for your shipping and processing needs with a dedicated Helpdesk team that attends to all your questions and guides you through our process

Contact Us

Our East coast locations service suppliers located in Canada and on the East coast of the United Sates. International suppliers are serviced at all PMR locations, depending on their shipping preferences and needs.

Call us

1-855-901-5050Office hours

Featured resources

Start working with a processor that provides you with the answers, not the questions.

Processing Knowledge

PMR Supplier Services: Animated Overview

PMR’s SSP is an overarching database that assists and supports suppliers through purchasing, monitoring, and evaluating their material.

Evaluation Intelligence

How to Avoid Getting Your Catalytic Converter Stolen

Catalytic converter theft is on the rise. Make sure your converter doesn't get stolen by following these safety guidelines.

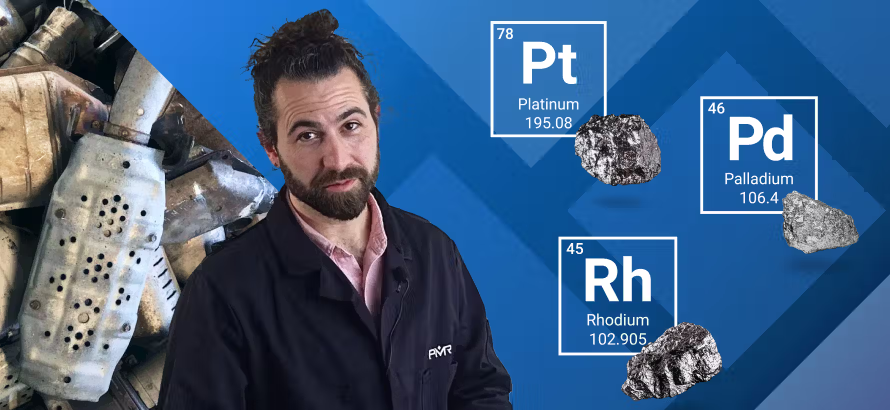

Catalytic converter 101

Why are catalytic converters so valuable and how their precious metals make them worth more than the rest of the car combined.

Catalytic converters are valuable because of the platinum group metals they contain: platinum, palladium, and rhodium. But there is much more to it than just precious metals.