Catalytic converter 101

Why are catalytic converters so valuable and how their precious metals make them worth more than the rest of the car combined.

As the cost of automobiles continues to rise, the question arises as to which car part is the most expensive. The answer varies depending on who you ask. Mechanics may see value in the labor, while dealerships may point to the cost of shipping. However, for recyclers, one small, yet crucial part of the car carries significant value—the catalytic converter—and its value can sometimes be puzzling. We wanted to simplify it as much as possible so we partnered with Thubprint, scrap metal aficionado, to dig deeper into the contents of catalytic converters and the future of the rare metals they contain.

Catalytic converters are essential for meeting modern environmental standards and are required on all passenger vehicles. But what makes catalytic converters so valuable? Why do their prices differ when scrapped, and how do recyclers determine their true value? The answer lies in their precious metal content. This article will explore the importance of catalytic converters and the factors that affect their value.

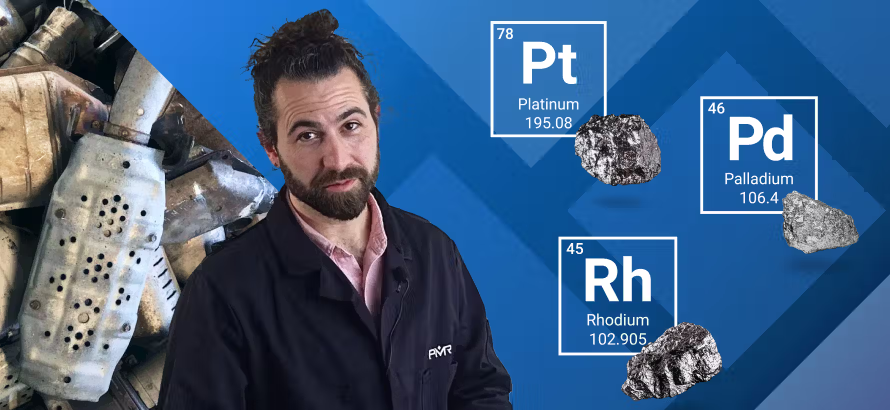

Which precious metals are found in catalytic converters?

Among the most valuable metals in the world are three platinum-group metals - platinum, palladium, and rhodium, which are all found in catalytic converters. These metals' value in the PGM market is even higher than that of gold. Catalytic converters require these metals for two primary reasons in vehicle exhaust systems.

Why are PGMs used in catalytic converters?

First, they act as catalysts. They cause reactions that chemically alter exhaust gasses while remaining unchanged themselves. Without PGMs, your engine emits nitrogen oxides, carbon monoxide, and hydrocarbons, toxic gasses. Platinum and rhodium draw nitrogen out of these oxides and allow free nitrogen and oxygen molecules to form nitrogen gas and oxygen gas. And platinum and palladium oxidize carbon monoxide and hydrocarbons into carbon dioxide and water vapor.

Secondly, The PGMs mentioned here are special metals that are very tough and durable. They can resist damage from things like acid, rust, and heat. This is important because they can be used in reactions that require high temperatures, like burning gasoline in a small metal box.

These special metals, called PGMs, only work this way in certain conditions. While some PGMs are used for making jewelry, electronics, and other things, most of them (60%) are used to make autocatalysts.

It's easier to get platinum, palladium, and rhodium from recycled catalytic converters than it is to make new material because it takes a lot of mined ore to get just a little bit of these metals. Rhodium is especially rare and is mainly found as a by-product when mining other metals like platinum, palladium, or nickel.

What are the specific values of these precious metals?

Extracting platinum group metals (PGMs) through mining is a demanding and costly process that requires considerable labor and energy. Coal is the primary source of energy for mines, and fuel is used for transportation, while skilled and paid workers are necessary to operate the mines. Extracting rhodium, in particular, is a challenging and rare task due to the small quantities of the metal that can be extracted at a time.

Why do PGMs prices fluctuate so much?

The prices of these metals are subject to significant fluctuations and can change quickly, depending on various factors such as supply and demand. In 2020, for example, the price of platinum rose from $700 to $1,000 per ounce after the outbreak of the COVID-19 pandemic. Despite this increase, the price of platinum remains relatively low compared to other PGMs, such as palladium, which is the primary metal used in catalytic converters. Over the course of one year, the price of palladium rose from $1,000 to $3,000 per ounce.

What makes Rhodium different from other PGMs?

Rhodium is a unique metal with a distinct characteristic of being utilized exclusively as a component in catalytic converters, and hence, it is not traded as frequently as other metals. The use of rhodium in catalytic converters is a relatively recent development as older converters primarily used platinum. Modern designs have led to the increased usage of rhodium, which has become a crucial component of catalytic converters.

Why are some auto catalysts nearly worthless compared to others?

There are several factors that can render catalytic converters worthless, with aftermarket converters and reject converters being typical examples.

Aftermarket converters vs. OEMs

Aftermarket converters are generally worth significantly less than Original Equipment Manufacturer (OEM) converters as they contain only 10% of the precious metals found in the latter. OEM refers to the original equipment manufacturer, indicating that the parts were produced by the same company that manufactured the vehicle. On the other hand, aftermarket parts are designed to serve as more affordable replacements and are often constructed to be compatible with as many vehicles as possible.

What are reject converters?

There are also instances where reject catalytic converters are produced due to manufacturing defects. If there is an issue with the ceramic brick during the production process, and it gets coated with precious metals, the resulting reject converter has no value in terms of precious metals. These reject converters can be identified by their white or yellow appearance, indicating that they have not been coated with precious metals. Despite having no value, suppliers may still attempt to purchase these units, which can be a risky endeavour. On the other hand, there are catalytic converters that are highly valuable as they have not been in use for 10-15 years, thus preserving their precious metal coating. This presents a challenge for recyclers as toll-refining is often necessary to determine the true value of a given catalytic converter.

Why is global demand on the rise for PGMs?

The global demand for PGMs appears to be increasing as the world makes significant strides towards achieving carbon neutrality and improving air quality. The tightening of emission regulations, the shift towards a hydrogen economy, and a resurgence in car sales are all factors contributing to the growing demand for PGMs, leading to an eventual increase in prices.

Will the transition to electric vehicles hurt the PGM market?

While the transition towards electrification in the auto industry may be gradual, hydrogen, hybrid, and conventional vehicles will continue to thrive. Hydrogen-powered vehicles offer a clean fuel alternative that produces only water vapor when burned. In these systems, platinum plays a crucial role as a catalyst. Even though hydrogen-powered vehicles are still in the developmental phase, the future of platinum in this sector is bright, indicating that the demand for this PGM will remain robust for many years to come.