PGM Recycling

PGM Recycling: Revolutionizing Metal Recovery and Sustainability

Welcome to the forefront of a sustainable future with PMR, the catalytic converter recycler dedicated to extracting every ounce of platinum, palladium, and rhodium from your material. This is your gateway to understanding the pivotal role you play in precious metal recycling, particularly platinum, palladium, and rhodium (PGMs) from catalytic converters. Let’s explore why PGM recycling is more than just extracting metals but a commitment to shaping a sustainable future.

Why PGM Recycling Matters

Resource optimization is now more important than ever. By participating in PGM recycling, you actively return valuable precious metals to industries that depend on them, contributing to the conservation of natural resources and promoting a circular economy.

Environmental Impact and Benefits of PGM Recovery

By recycling catalytic converters, you help reduce the need for new mining activities. Mining PGMs is notorious for its environmental impact, leading to deforestation, soil degradation, and habitat destruction. Recycling PGMs not only conserves precious resources but also minimizes our global carbon footprint.

Economic Impacts and Aspects of Precious Metal Recycling

Mining PGMs is expensive, costing companies millions of dollars to maintain mines, transport material, and transform mined materials into useable form. Extracting PGMs from spent auto catalysts, however, is 10 times less expensive than mining because it requires less human workforce and consumes less energy.

It’s also a cost-effective way of meeting the rising demand for PGMs, especially since mines cannot keep pace. Mines are responsible for 80% of all global PGM supply, but when they can’t meet the growing demand, the world relies on recycled catalytic converters.

For this reason, PGM market prices change according to this supply-demand dynamic. For example, a high demand and low supply typically mean higher market values, whereas low demand and high supply result in lower prices.

To explore examples of how supply, demand, and other driving factors affect the market prices of PGMs, take a look at our PGM Report for 2024 – 2030.

The Essential Guide to PGM Processing and Extraction

When your converters arrive at a processing facility, they’re cut and decanned to release the ceramic core inside—where all the precious metals are contained. Specialized machinery then crushes and commingles the ceramic into a homogenous powder, which is then sampled for assay analysis.

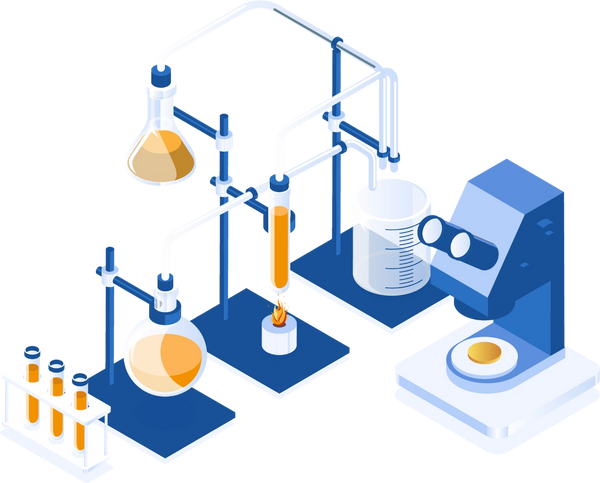

Assay Analysis

In the lab, processors analyze your material using two primary technologies: X-ray Fluorescence (XRF) benchtop and Inductive Coupled Plasma (ICP). These devices analyze the exact amount of platinum, palladium, and rhodium contained in your converters.

This is where you get paid. You get a comprehensive assay report, detailing your troy ounce recovery figures, parts per million (PPMs), metal return percentages, and more. This information allows you to see how many ounces of platinum, palladium, and rhodium you have, helping you hedge your PGM market prices accordingly.

Smelting and Resale

Once the analysis is complete, your metals move to the smelting phase, where tons of precious metals are fed to an arc-furnace. Your metals undergo chemical leaching and separation, transforming them into metal sponges or their pure elemental state. This is when your metals are now considered physical ounces and are ready to return to the global market for purchase, resale, or trade.

Payment on Recovery: Getting the Most from Your Converters

Many recyclers choose not to get their converters processed and prefer selling to converter buyers instead. If you’re selling this way, you might not be getting a fair price for your material. That’s because by-the-piece buyers overlook the unique composition of each converter and won’t pay you for the metals inside.

You deserve to be paid for what you have. Working directly with a catalytic converter processor ensures that every ounce of value is extracted from your material and returned into your business. For example, PMR uses all-enclosed machinery designed to capture every ounce of ceramic and dust content. This way, once your material is analyzed, you’ll get paid based on the exact amount of precious metals contained in your converters.

Payment on recovery ensures that you benefit from the true value of your material, maximizing your returns so that you can focus on what really matters: growing your business.

How PGM Recycling is Transforming the Automotive and Scrap Metal Industries

Every year, the automotive industry uses up to 60% of all PGMs available to manufacture catalytic converters for gasoline, diesel, and hybrid vehicles. Without PGMs and without catalytic converters, carmakers wouldn’t be able to make and sell any new vehicles.

PGM recycling allows essential precious metals to return to the supply chain, ensuring production and sales of new vehicles keep up with demand—and it would all be impossible without scrap metal and automotive recyclers.

With the demand for recycled PGMs skyrocketing—mostly due to its cost-effectiveness and low environmental impact—you become a key player in returning these metals to the circular economy.

Automotive Recyclers

Buy scrap cars and benefit from an extra revenue by selling your converters. This way, you’ll not only participate in the return of PGMs to the economy but also maximize your profits.

Scrap Metal Recyclers

The world needs PGMs. Take advantage of the unique position you hold and ship your converters to a processor. This way, you secure the true value of your material and participate in sustainability efforts.

Industry Challenges and Strategies to Overcome Them

This industry isn’t immune to market challenges. And to thrive in any market climate, you need strategies that allow you to protect your investments and remain competitive. Here’s what you can do:

Low Lot Requirements

In low volume markets, you shouldn’t have to meet high lot requirements. With low minimums, you can ship as you collect and keep a steady income.

Fast Turnaround

Getting paid quickly is key to staying competitive. With a fast turnaround, you can secure a continuous revenue stream, keep buying more converters, and grow your business.

Tolling

Tolling options allow you to keep a secure bank of your metal ounces at a processing facility, allowing you to get paid whenever the market prices meet your needs.

Combating Theft and Protecting Your Investment

Catalytic Converter Legislation

Rising converter theft has forced lawmakers to draft rigorous laws that govern the sale, purchase, and trade of catalytic converters. They require identification and documentation proving converter/vehicle ownership and business registration. These protocols are known as Anti-Money Laundering (AML) and Know Your Customer (KYC) guidelines.

Converter regulations can change quite rapidly, and we understand that they can be confusing to keep up with. That’s why we created a guide to help you stay on top of changing legislation, ensuring your transactions remain accountable and secure.

Staying on the Right Side of the Law

We understand that spotting red flags can be tricky. Here’s what you can do to ensure no illegal converter unit ends up in your possession:

Refuse Shiny New Converters

Refuse Cash-Only Transactions

Avoid Converter Sellers With No Dismantling Connections

Avoid Any Sellers Who Accept Any Offer Without Hesitation

Whether you’re buying and selling converters, it’s important to have the right documentation. Here’s what you should be requiring or providing:

- Photo ID and vehicle identification numbers (VINs).

- Business registration.

- Any recycling licences and permits required by your local and state laws.

Compliance Considerations for Processors

Catalytic converter processors like PMR believe in legitimate, honest business. That’s why we enforce rigorous AML and KYC protocols, ensuring accountable and secure transactions across all supplier accounts. Here’s how PMR is leading the way:

Cash-only transactions have been refused for over a decade.

Proof of legal business registration and/or date of incorporation, along with photo ID, is required, where applicable.

Suppliers must provide all relevant state and local recycling licenses and permits required by law.